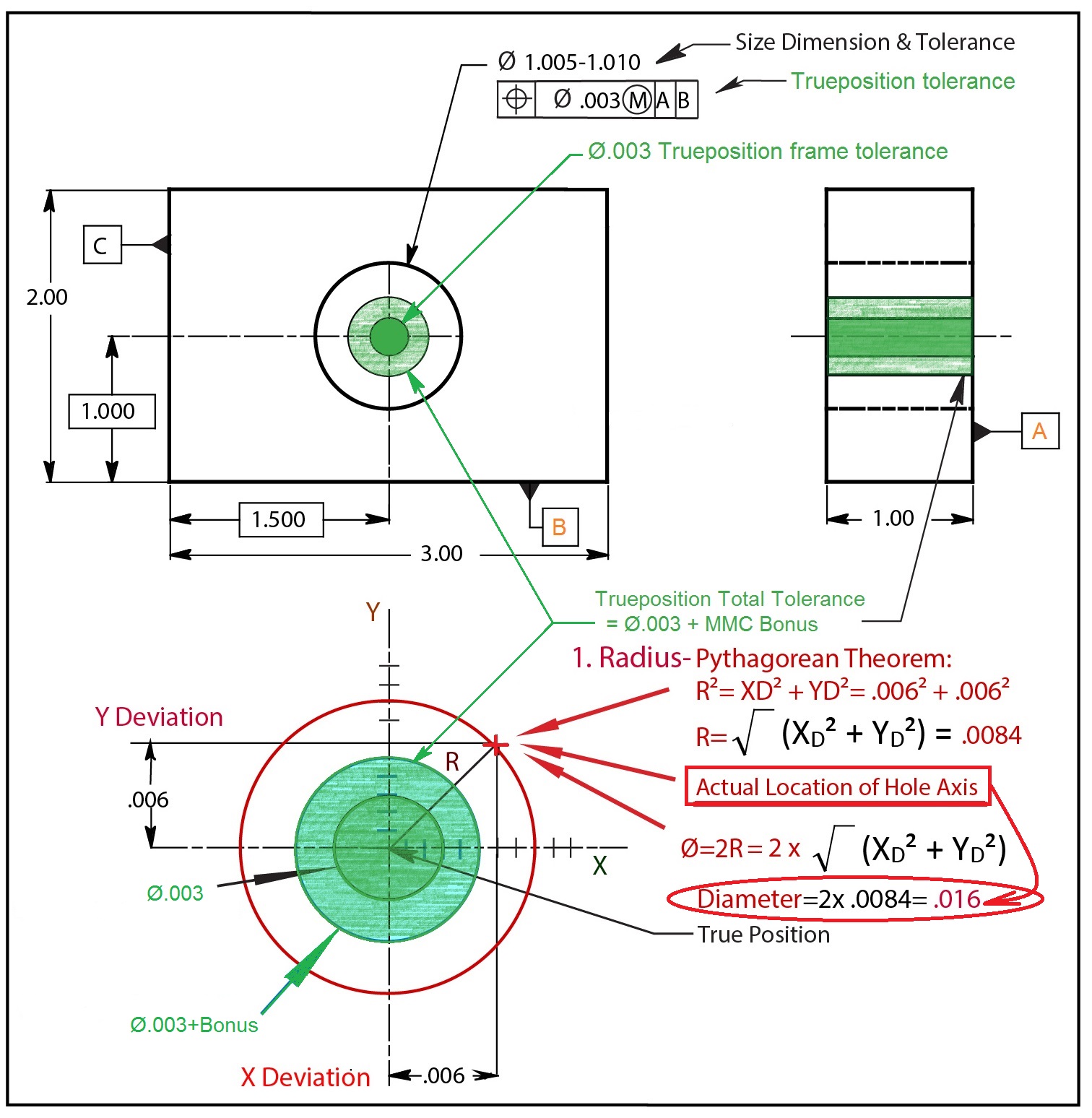

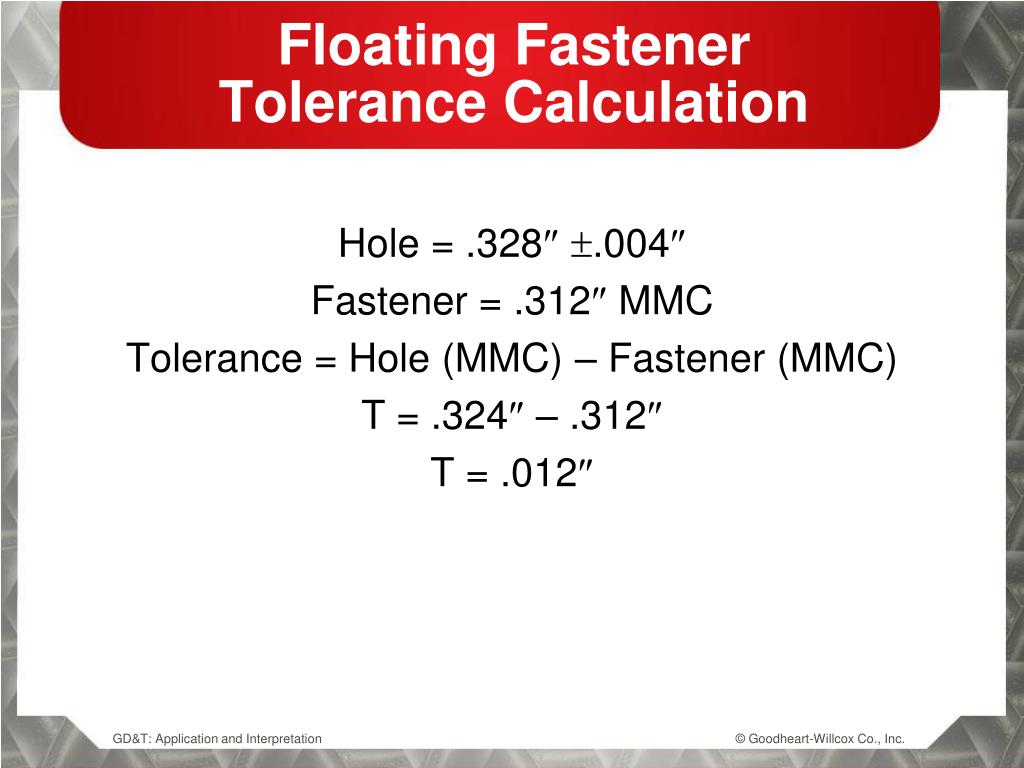

Divide the result between the threaded & clearance hole. Subtract the screw max major dia from the minimum hole diameter.Ģ. Take a look at the examples in my excel sheet hopefully they'll help you.ġ. Use instead the equation drawoh gives which is the same as in my excel sheet. It isn't for calculating the required tolerance to ensure fit. The chart SeasonLee posted is just for converting +- dimensions to equivalent positional diameter. You don't need to worry about what the tap size is, you need to worry about what the clearance hole size in the mating part is. JLang17, I always use the screw max dia for my calculations. JHG RE: Calculating Positional Tolerance KENAT (Mechanical) 21 Jan 09 14:19 If you are clamping a casting with cast-in holes, to a machined mount, you may want to mess with the model a bit. Also, it is assumed that both parts are being made to the same tolerance. Otherwise, you must account for the perpendicularity of a screw in an angled hole. In the case of the screw, it is assumed that the material being clamped is thin. Note that drilled holes are oversized and screw major diameters are undersized. For a screw in a tapped hole, the geometric tolerances should be C/2. It is always possible that the designer was trying to do something else.Ī convenient estimate is that a clearance hole for a bolt requires a positional tolerance equal to the hole clearance, C= DRILL- SCREW. This is all assuming that your X/Y tolerance was intended to allow a hole to be. Most likely, you are viewing using Dropbox website or another limited browser environment.The positional tolerance equivalent to ±.01" X/Y tolerances is Ø.028". The webpage is not working since JavaScript is not enabled. This is a single tolerance and size event.

For an internal feature of size specified at MMC, Resultant Condition = LMC + Geometric Tolerance allowed.

Resultant Condition = Worst case tolerance boundary generated by the cumulative effects of size and geometric tolerance. For an internal feature of size with MMC specified, Virtual Condition = MMC - Geometric tolerance, or as-manufactured size - allowed geometric tolerance at that size. Virtual Condition = Tolerance boundary that is constant for all sizes and generated by the cumulative effects of size and geometric tolerance at MMC. Related: External MMC vs Feature Size Tolerance Chart Tool Calculator This calculator tool will create a Geometric Size vs MMC Maximum Material Condition Tolerance Chart per. Internal feature of size Maximum Material Condition MMC Size Calculator. Tolerances, Engineering Design & Limits & Fits Maximum Material Condition MMC vs Internal Feature Size Tolerance Chart Calculator

0 kommentar(er)

0 kommentar(er)